Structure of the Global infrared heaters

Among the IR heaters available on the market, we differentiate between two types of devices:

- Heating wire

- Heating mat, heating foil

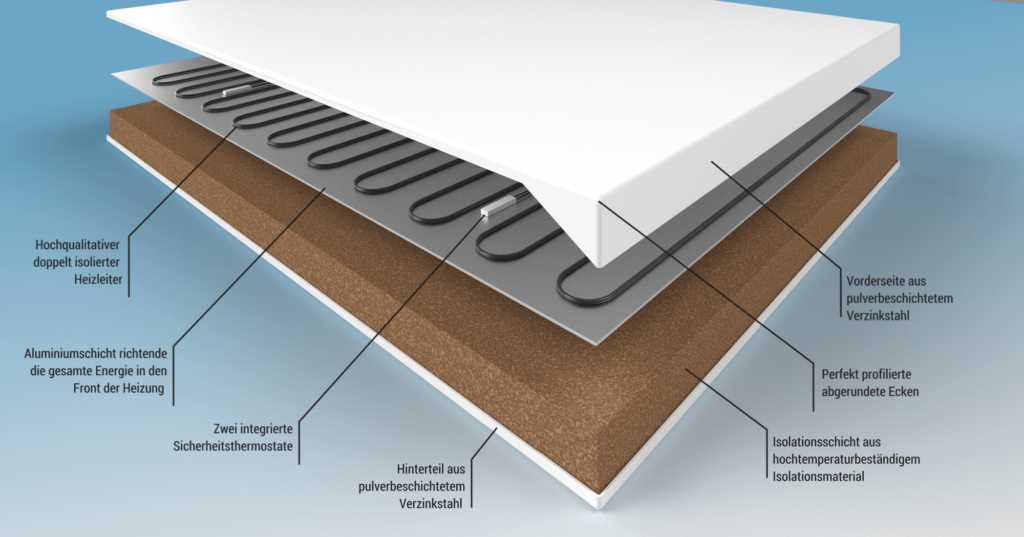

Advertisement. 1: Our panels are based on a high quality heating wire, the following diagram illustrates the structure of our panels:

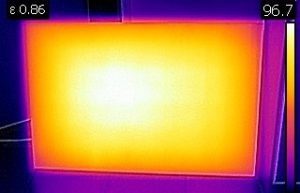

The photo below shows the recording of our infared heater in a thermal imaging camera. It shows an even temperature distribution on the surface, it heats up evenly and the entire surface emits infrared heat. The surface temperature is ideally in the range of 90-100°C. To even speak of infrared, the temperature of the surface must be at least 65-75 ° C. From this limit onwards, the ratio of wave heat compared to convection changes in favor of wave heat. However, only at a surface temperature of about 100°C do we speak of a very high proportion of wave heat in relation to convection. On the other hand, the temperature for panels installed within touching distance should not be higher than approximately 105°C to meet safety standards. The effect of an even temperature distribution is achieved by using a high-quality heating wire, an insulating layer inside the device and an aluminum directional panel that increases efficiency.

Regarding 2. The second method of producing heating plates is to use a heating mat or foil.

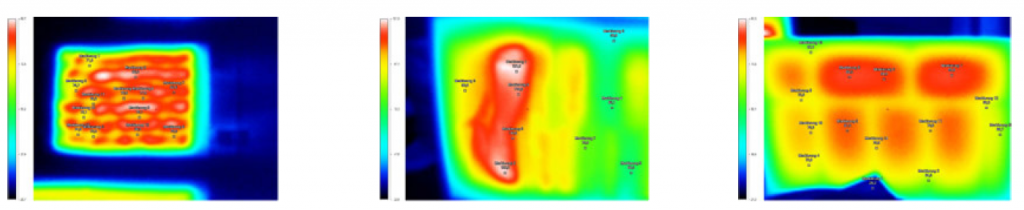

The following photos show a thermal imaging camera image of panels from manufacturers who use heating mats or heating foils for production, on which there are warm areas (often exceeding the permissible temperature) mixed with areas of too low a temperature, it means only parts of the surface of such devices emit infrared heat, and the rest of the surface functions as an ordinary convector.

GLOBAL heating panels above the norm

(NEW STANDARD: DIN EN IEC 60675-3)

The construction way of our heaters results of a very high wave heat (infrared wave) emission factor:

In the year 2023 our infrared heating panels have been tested against the IEC 60675-3 standard and we are pleased to announce that these measurements passed without any problems. The required value of 40% was significantly exceeded by our panels.

This means that from now on all our panels can be called “Infrared heating according to the IEC 60675-3 standard”

We are one of the first companies on the European market meeting this standard. We are very proud of this!

Our heating panels are “Real infrared”.

Explanation:

The new DIN EN IEC 60675-3 standard is the first in the world to establish a method for determining the radiant efficiency of domestic electric direct heating appliances.

The standard was originally developed in the VDE/DKE (German Commission for Electronics and Electrical Engineering) working group based on research results at TU (Technische Universitaet) Kaiserslautern. It was then refined and further developed at the international level in the working group of the International Electrotechnical Institute Commission (International Electrotechnical Commission, IEC). IEC is the world’s most important standardization organization in the field of electrical engineering and electronics, headquartered in Geneva. The IEC standard is a key quality criterion in retail.

The measurements necessary to determine the radiant efficiency are performed in a standardized test room and, as described above, the actual effective thermal power transferred to the room surface is measured. In addition, a limit value is established at which electric room heating is considered infrared heating in accordance with this standard, namely from 40%. Starting from this threshold, the thermal power transferred in the form of infrared radiation predominates compared to the other two types of heat transfer: both convection and conduction.

This definition is crucial because it is only then that the infrared heating effects described above take place, such as predominantly heating the surface rather than the air in the room. Since the term infrared heating was used quite arbitrarily on the heating equipment market so far – even fan heaters were offered as infrared radiators – there was no guarantee of obtaining the above properties for all products offered under this name.

The definition of radiant efficiency in the DIN EN IEC 60675-3 standard provides a basis on which heating can be classified as infrared heating.

The standard also specifies how to measure the warm-up time (high-class infrared heating heats up to full operating temperature in less than 5 minutes).

The most important criterion for the quality of infrared heating is the radiation efficiency, the second most important is the heating time, determined in accordance with the standard.

(Source: Dr. Ing. Peter Kosack „Leitfaden Infrarotheizung”, 2020)